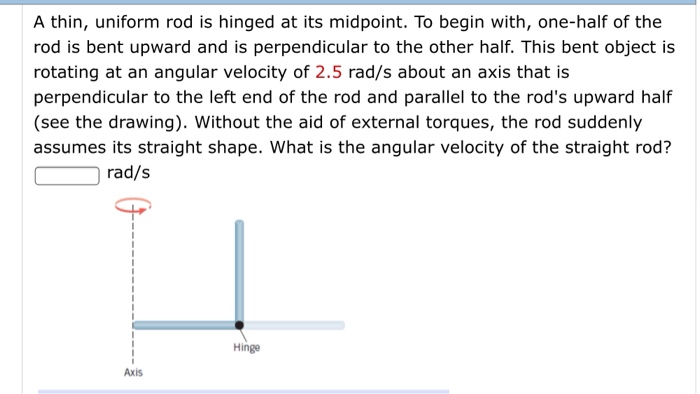

A thin uniform rod is hinged at its midpoint – A thin uniform rod hinged at its midpoint presents a captivating subject for exploration, offering insights into the interplay of mechanics, equilibrium, and dynamics. This comprehensive analysis delves into the significance of the hinge point, examines the rod’s characteristics, and investigates its behavior under various conditions, unveiling the practical applications and design considerations associated with this fundamental element.

The unique properties of a thin uniform rod, hinged at its midpoint, give rise to intriguing phenomena and practical applications. Its behavior is governed by the interplay of its physical characteristics, such as length, mass, and material composition, and the forces acting upon it.

Understanding the dynamics of this system is crucial for engineers, physicists, and anyone seeking to harness its potential.

1. Hinge Point Analysis

The hinge point at the midpoint of the rod plays a crucial role in its stability and motion.

It allows the rod to rotate freely about the hinge, providing a fixed axis of rotation. This hinge point effectively divides the rod into two equal segments, ensuring symmetrical behavior.

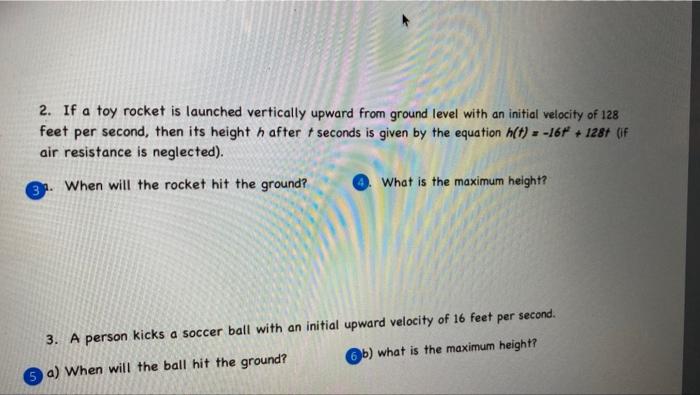

The hinge point also influences the rod’s stability. When the rod is in equilibrium, the hinge point acts as a pivot, preventing any lateral displacement. However, if the rod is disturbed from equilibrium, the hinge point allows it to oscillate about its axis.

Examples of how the hinge point affects the rod’s behavior include:

- A seesaw with a child on each end: The hinge point allows the seesaw to move up and down, but prevents it from falling over.

- A pendulum: The hinge point at the top of the pendulum allows it to swing back and forth, but keeps it from rotating completely.

2. Rod Characteristics

A thin uniform rod is characterized by its length, mass, and material properties.

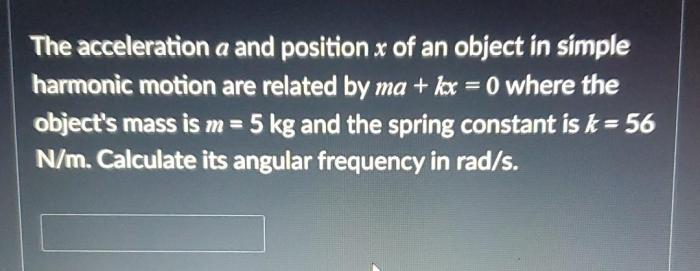

The length of the rod determines its moment of inertia, which affects its resistance to rotation. A longer rod has a larger moment of inertia, making it more difficult to rotate.

The mass of the rod influences its overall weight and affects its dynamic behavior. A heavier rod will have a longer period of oscillation and a lower natural frequency.

The material of the rod determines its stiffness and elasticity. A stiffer rod will have a higher natural frequency and a shorter period of oscillation.

Examples of thin uniform rods and their applications include:

- Bridge girders: Long, thin rods used to support the weight of a bridge.

- Diving boards: Flexible rods that allow divers to bounce and perform stunts.

- Tuning forks: Thin rods that vibrate at a specific frequency, used for tuning musical instruments.

FAQ Section: A Thin Uniform Rod Is Hinged At Its Midpoint

What is the significance of hinging a rod at its midpoint?

Hinging a rod at its midpoint creates a unique equilibrium point, allowing the rod to rotate freely about this axis. This configuration simplifies the analysis of forces and motion, making it an ideal system for studying rotational dynamics.

How does the hinge point affect the rod’s stability?

The hinge point provides stability to the rod by preventing lateral movement. It ensures that the rod can only rotate about the hinge axis, eliminating any tendency to buckle or bend under external forces.

What are some real-world applications of thin uniform rods hinged at their midpoints?

Thin uniform rods hinged at their midpoints find applications in various fields, including: pendulums (timekeeping), balance beams (weighing), and torsion springs (energy storage).